Manufacturing and inspection equipment

Manufacturing and

testing equipment & parts

Providing custom products applying die bonder core technologies

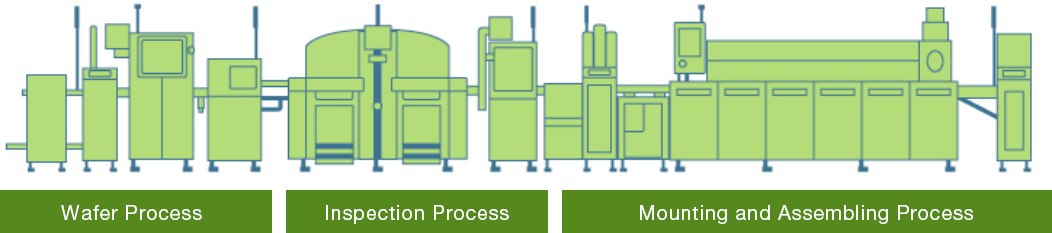

Manufacturing and inspection equipment

for laser diodes

In addition to information communication, laser diodes are used for a variety of applications, such as in projection equipment, 3D sensing, processing machines, equipment installed in vehicles, and medical equipment. As customers are demanding even higher precision, higher product quality, and higher productivity, we engage in sales and support with an assortment of manufacturing and inspection equipment from manufacturers who claim the top market share inside and outside Japan. This includes equipment from wafer processes to mount assembly and inspection processes. In addition, we also provide proposals for one-stop solutions, such as support from the product design stage of the customer, as well as proposals for components.

- YSystems PL mapper

- Alphax LD testing and sorting system

- Four Technos die bonder

- Four Technos wire bonder

- Alphax LD temperature characteristic testing system

- FTD alignment and welding system

- Welding relational products

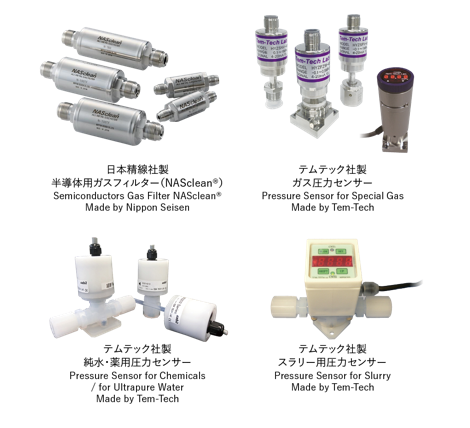

Gas filters/Pressure sensors

We provide filters and pressure sensors that are essential for managing the filtration and low of gas, pure water, and chemicals used in the manufacturing processes of semiconductors, touch panel displays, solar cell panels, etc. Since our founding, we have been using our proprietary technology and highperformance metal filters manufactured using NASLON stainless steel fiber uniquely developed by Nippon Seisen (a top manufacturer of stainless steel fiber) to make proposals for pressure sensors of Tem-Tech Lab. We have been responding to the highprecision and special applications of various producers of manufacturing equipment inside and outside Japan.

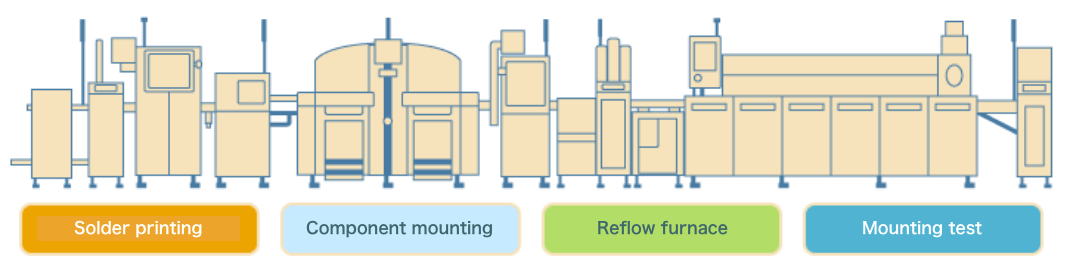

Mounting board manufacturing and testing systems

- Teradyne In-circuit testers (ICT)

【Mounting test】 - Multi functional testers (FCT)

【Mounting test】 - Viscom Solder printing testing systems (SPI)

【Solder printing】 - Viscom Automated Optical Inspection Systems (AOI)

【Mounting test】 - Viscom Manual X-ray Inspection Systems (MXI)

【Mounting test】 - Viscom Automated Optical + X-ray testing systems (AOXI)

- Metal mask laser processing systems

【Solder printing】 - Mounting data generation software

【Component mounting】 - Transfer carriers

【Reflow furnace】 - acSil – Carrier Tape for FPC Assembly

【Reflow furnace】 - In-System programming tool(ISP)

【Mounting test】

Hard disk manufacturing and testing systems

- Guzik Spin stands (DTR3000)

Other manufacturing and testing equipment & parts

- High-perfomance test sockets

- Industrial PCs and measuring/control boards

- Industrial network equipment

- M3U –Low Voltage Cable/Harness Tester

- HVX – High Voltage Test System

- Standard Connector Board

- Custom Interface/fixtures

For inquiries about Manufacturing and testing equipment & parts

For inquiries about our products and business negotiations

Contact by formContact by phone

+81-(0)3-6412-6032