製造・検査装置

製造・検査設備/関連部品

国内外トップシェアを誇るメーカー各社の製品を販売・サポート。

あらゆるものがインターネットでつながるIoT時代の本格的な到来にともない、膨大なデータの高速処理、高速伝送、大容量ストレージ、そして、AIによる無人化処理システムなどの技術は日々進歩をしてします。それらを支える基盤技術・デバイスである半導体製品も、爆発的に需要が高まっています。こうした重要な半導体製品の製造や検査にかかわる設備・部材に関し、国内外で高いシェアを誇る各社メーカーの製品を取り揃え、販売・サポートを行っています。

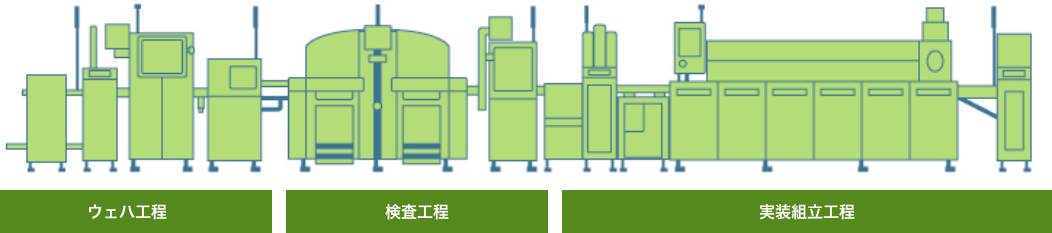

レーザーダイオード用製造・検査装置

情報通信に留まることなく、投影機器、3Dセンシング、加工機械、車載関連、医療機器など、いっそう用途が広がる半導体レーザ。さらなる高精度化、高品質化、高い生産効率が求められる中で、国内外でトップシェアを誇るメーカー各社の製造・検査設備をウェハ工程~実装組立・検査工程まで取り揃え、販売・サポートだけではなく、お客様の製品設計段階からのサポートや部材の提案などを含めたワンストップソリューションの提案を行っています。

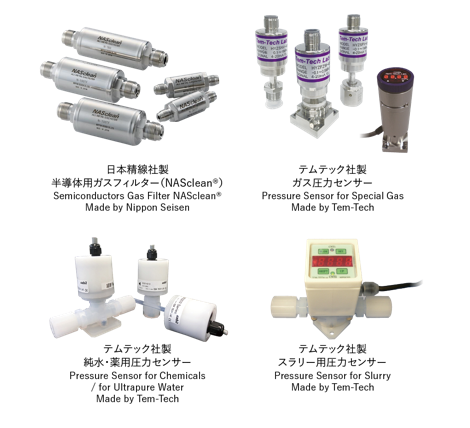

ガスフィルター / 圧力センサー

半導体・フラットパネルディスプレイ、太陽電池パネルなどの製造工程に用いられるガスや、純水・薬液の濾過や流量管理に欠かせないフィルターや圧力センサーを提供しています。ステンレス鋼線のトップメーカーである日本精線が独自に開発したステンレス鋼繊維「ナスロン」などを用いて製造する高機能メタルフィルター、独自の技術で創業以来、国内外の様々な製造設備メーカーに高精度かつ特殊用途にも応えてきたテムテック研究所の圧力センサーを提案しています。

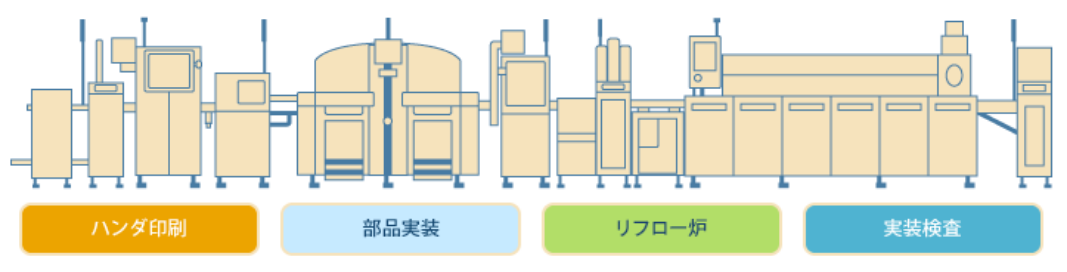

実装基板製造・検査

ハードディスク製造・検査

ヘッド&メディア検査装置

製造検査装置関連

製造・検査設備/関連部品に

関するお問い合わせ

製品に関するご質問・ご商談等お問い合わせ

お問い合わせフォームお電話でのお問い合わせ

03-6412-6032